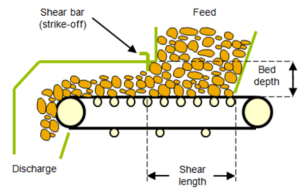

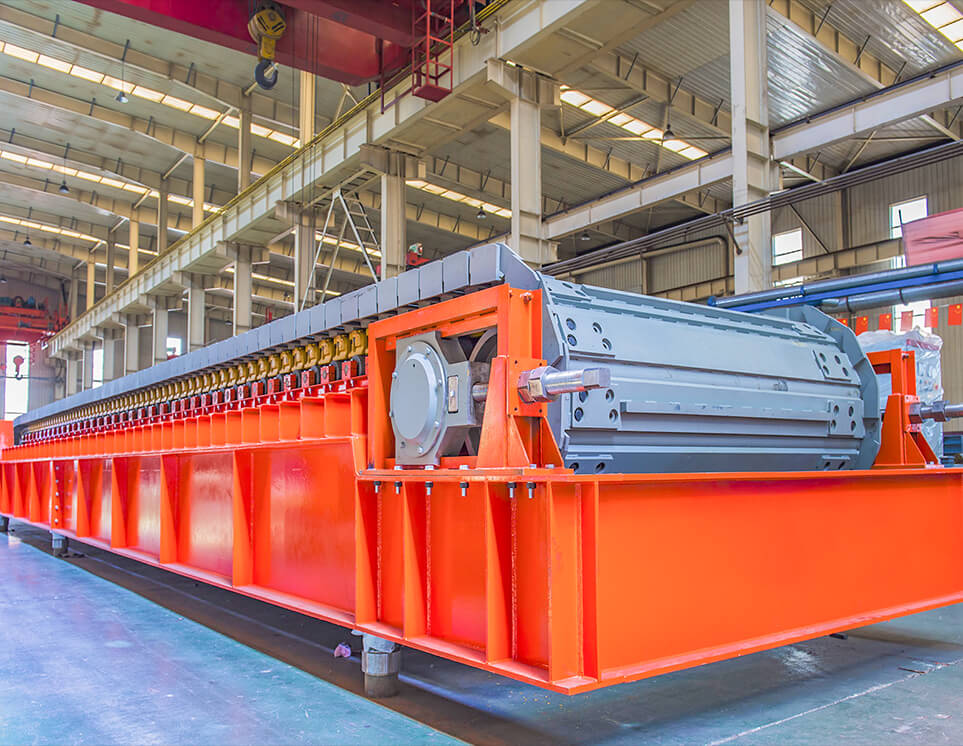

Apron Feeder consists of drive wheel device, tail wheel tension device, pan- chain device and transmission device. After the head sprocket is driven, the traction chain in the pan- chain device meshes with the sprocket to drive the entire pans to move along the longitudinal center-line and the roller travels along the track fixed on the frame, thereby completing work. The material discharged from the silo/hopper is transported along the conveying line to the front of the body for continuous and uniform feeding.

1. Using 16Mn steel plate with high strength and stiffness, to withstand great impact.

2. Standard track chain, no lubrication or deviation, for interchangeability and long service life.

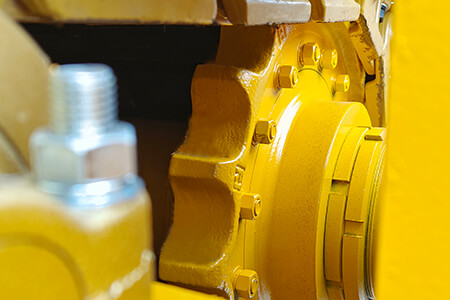

3. The sprocket material is made of high strength alloy steel and quenched, which has excellent wear resistance.

4. Equipped with composite spring on the tail part, which can effectively buffer the impact load of the chain.

5. Segmented drive sprockets, easy to maintain without removing the chain plate.

6. Traction chain and load chain are separated, so the dynamic load is small to achieve exteneding life.

Model | Pan width | Speed | Max feeding Size (mm) | Rail | Capacity | Length(m) |

BL800 | 800 | 0.01~0.25 | 350 | / | 50~350 | 2~15 |

BL1000 | 1000 | 0.01~0.25 | 470 | 1 | 100~510 | 3~20 |

BL1200 | 1200 | 0.01~0.2 | 650 | 1 | 120~595 | 3~20 |

BL1400 | 1400 | 0.01~0.2 | 680 | 2 | 140~850 | 6~20 |

BL1600 | 1600 | 0.01~0.2 | 700 | 2 | 320~1300 | 6~20 |

BL1800 | 1800 | 0.01~0.15 | 800 | 2 | 500~1560 | 8~20 |

BL2000 | 2000 | 0.01~0.15 | 1000 | 3 | 500~1850 | 8~20 |

BL2400 | 2400 | 0.01~0.15 | 1500 | 3 | 500~2700 | 8~20 |

BL2800 | 2800 | 0.01~0.15 | 1800 | 4 | 1000~4000 | 10~20 |

+86-539-8327899 | +86 15963938391

+86-539-8327899 | +86 15963938391

steven@lydot.cn

steven@lydot.cn

steven@lydot.cn

steven@lydot.cn  Fine Jaw Crusher

Fine Jaw Crusher Symons Cone Crusher

Symons Cone Crusher Jaw Crusher

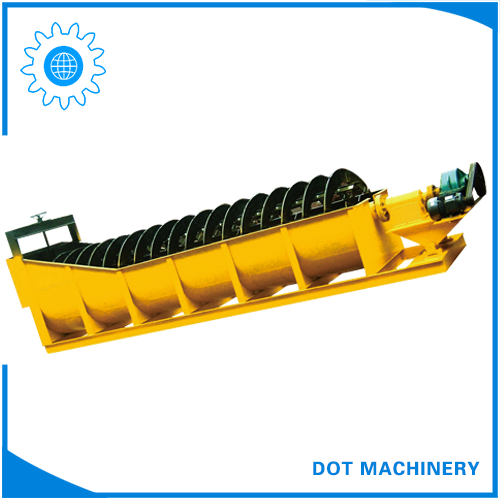

Jaw Crusher LX Sand Washing Machine

LX Sand Washing Machine Big Jaw Crusher

Big Jaw Crusher Spring Cone Crusher

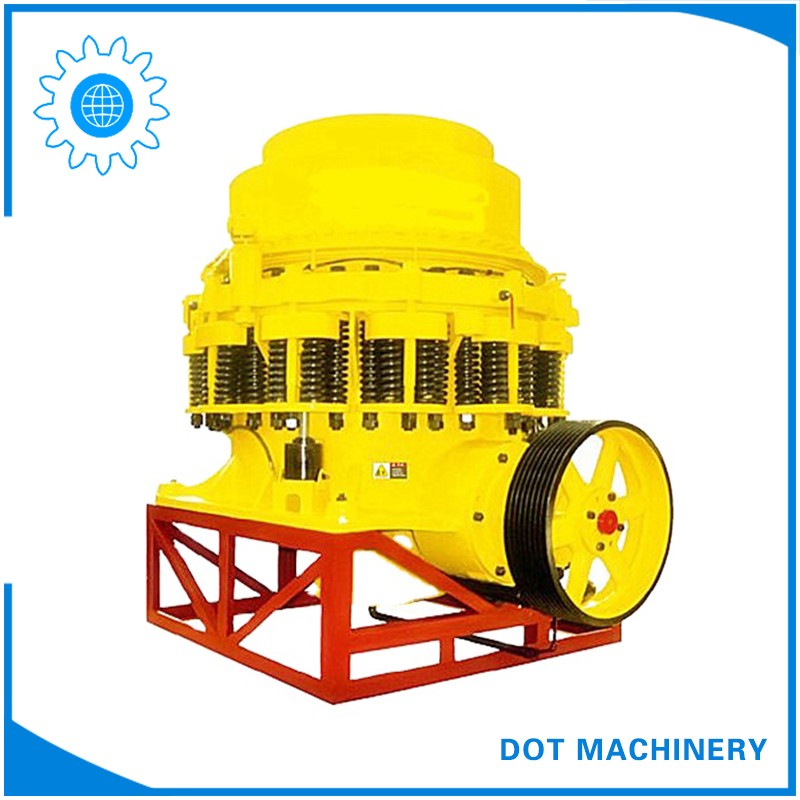

Spring Cone Crusher Impact Crusher

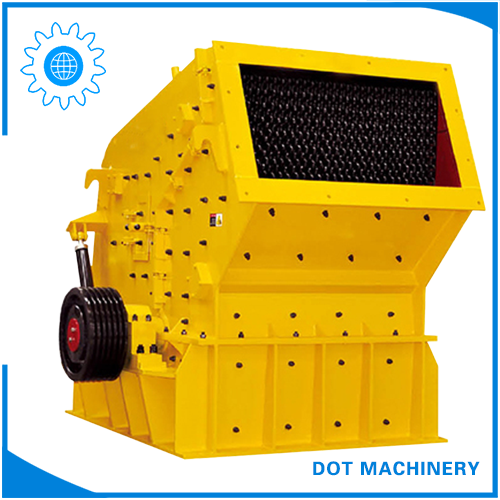

Impact Crusher Vertical Shaft Impact Crusher

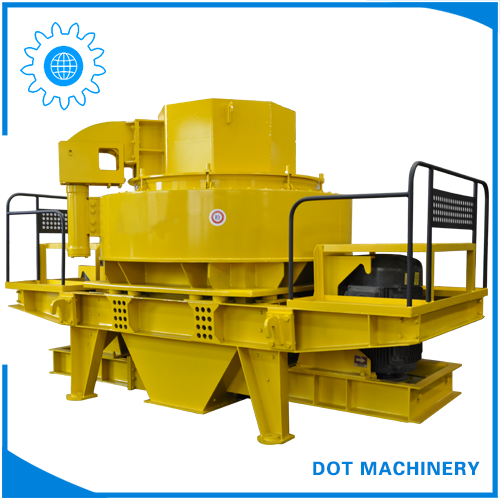

Vertical Shaft Impact Crusher