How To Configure Sand And Gravel Aggregate Production Line?

How To Configure Sand And Gravel Aggregate Production Line?

A complete sand and gravel aggregate production line is compose of crushing system, screening system, sand production system (there is no this system if customers do not need artificial sand), storage and delivery system, dust removal system.

Many customers wonder how to configure and design complete sand and gravel aggregate production line. Here are the key points.

I.Crushing System

1.1 Selection principle of crusher

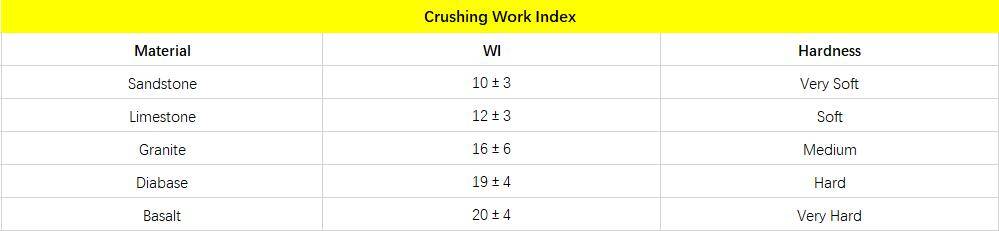

The crushing system is mainly composed of coarse crushing, medium crushing and fine crushing (shaping). The selection of equipment at each stage is mainly determined by the crushing work index, abrasion index, maximum feeding size and product quality requirements of the ore.

The typical processes of the crushing system are: single-stage hammer crusher system; jaw crusher + impact crusher system; jaw crusher + cone crusher system; jaw crusher + impact crusher + vertical shaft impact crusher system and jaw crusher + cone crusher + cone crusher system.

The selection of the crushing system should be based on the material characteristics, product shape and market demand.

II.Screening System

The design points of the screening system mainly include: Reasonable selection of screen area;

The chute between the upstream belt conveyor and the vibrating screen must be designed correctly to ensure that the raw materials can be spread on the entire screen;

The specifications of dust collector should be reasonably configured to ensure to meet environmental protection requirements;

The chute between the vibrating screen and downstream belt conveyor should be considered abrasion and noise protection.

III.Storage And Delivery System

The finished products are generally stored in sealed steel warehouses (or concrete warehouses) and steel structure sheds. The corresponding delivery system of the storage warehouse is an automatic car loader, and the corresponding delivery system of the steel structure greenhouse is forklift truck loading.

The per-unit storage investment of steel warehouse is higher than steel structure shed, but it has less dust emission and the automatic loading efficiency is high. Steel structure shed has lower per-unit storage investment, but its working environment is poor and the loading efficiency is low. In areas with strict environmental protection requirements, sealed steel warehouse (or a concrete warehouse) is preferred, which is more conducive to environmental protection acceptance.